PLC Interview Questions and Answers for Beginners

Q1. What is PLC?

PLC or Programmable Logic Controllers are industrial computers that control automated devices and processes. These systems combine hardware and software components that allow them to monitor inputs and regulate outputs, such as turning them on or off according to their pre-programmed logic.

Q2. What are the types of PLC?

When it comes to Programmable Logic Controllers (PLCs), there are two main types.

Compact PLC: It is a controller whose initial configuration cannot be altered as all the components are integrated into the unit.

Modular PLC: It is a controller that allows multiple expansions of the PLC system through different modules.

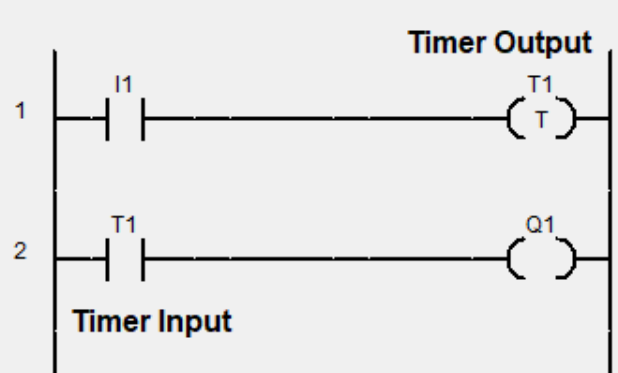

Q3. What is rung?

In LD programming, the numbers of the horizontal lines are represented as the “rungs”.Q4. What is the rack or chassis?

The modular PLC consists of a number of input or output modules, the controller processor, and the communication controller. This hardware assembly of these modules is called as “Rack or Chassis”.

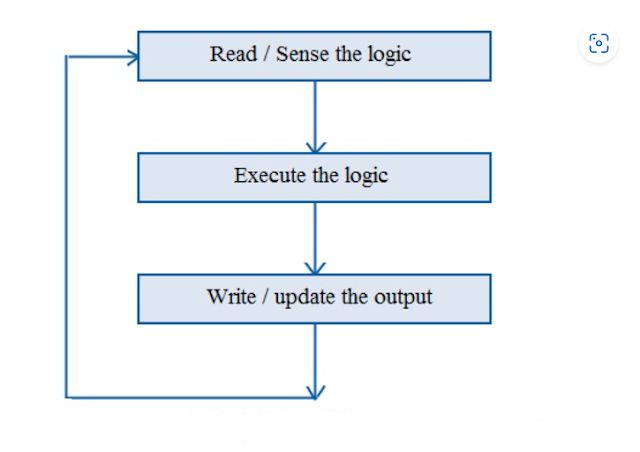

Q5. What is the PLC Scan Cycle?

Q6. What is the Redundant System?

The redundant system is a replica of the original system. When the original system breaks down redundant system takes charge of the original system and performs all the required operations.

Q7. Explain Program mode, Run mode, and Test mode in PLCs.

Program Mode: It refers to a process used for new programs or updating existing ones. As soon as an administrator goes into program mode, all ladder I/O and other related outputs are put on hold so they don’t interfere with programming changes being made.

Run Mode: In Run mode, the running user program is monitored and executed as specified. The data that has been entered into memory locations can also be read or updated in this mode. Additionally, any changes made to the inputs will cause immediate action from the PLC system, according to its previously programmed logic flowchart.

Test Mode: Test mode is a programming feature that allows one to check the functionality and accuracy of an implemented program without energizing any devices connected to it. It minimizes risks associated with operating actual machinery or outputs.

Q8. What are the advantages and disadvantages of modular PLC?

The advantages of modular PLC are:

It is a viable solution for catering to the changing demand of processes because the modular type of PLC allows its capacity to be scaled.

It offers simpler troubleshooting that reduces system downtime.

The disadvantages of modular PLC are:

It is costlier than compact PLC. The programming of this PLC is complex due to flexibility in its configuration.

Q9. What are the advantages and disadvantages of compact PLC?

The advantages of compact PLC are:The disadvantages of compact PLC are:

Q10. Explain the Instruction List and Structured Text.

Instruction List is a low-level PLC programming language that contains a simple series of instructions where each instruction is made up of an operator. These operators are further made up of one or more operands.

Structured Text is a high-level PLC programming language that uses statements to perform functions. It is a concise textual language quick to execute and read. It is used for manipulating data, barcode parsing, searching data, looping, etc.Q11. Explain Functional Block Programming and Sequential Function Charts.

Functional Block programming is a graphical PLC programming language that consists of various kinds of blocks with inputs and outputs. Devices connected to a PLC are linked with an input and variables are sent to output. The blocks are connected to each other, where the output of one block is used as input for another block. These define the function of a system.

Sequential Function Charts is a graphical PLC programming language that contains steps and transitions to control a program’s operational flow. Steps are actions to be performed, and transitions are logical conditions necessary to be met before going ahead with the next step.Q12. What are Sinking and Sourcing?

In sinking circuits, the load is connected directly to the ground so current flows from positive (+DC ) towards negative (-DC). On the other hand, in sourcing circuits, power is provided by an external source of 24-volt direct current, which means that electricity will flow outwards to any loads/apparatus attached.

Q13. What is Uploading and Downloading in PLC?

Uploading and downloading are terms used when discussing the transfer of data between a Programmable Logic Controller (PLC) and another system. Uploading refers to sending/transferring data from the PLC into another device or computer while downloading is transferring information from the other device back into the PLC.

Q14. What is the purpose of a Sensor?

Q15. What are the different PLC brands?

The various companies are invented their own PLC brands. Here are some popular PLC brands.- ABB PLC

- AB (Rockwell) PLC

- Siemens PLC

- Delta PLC

- Mitsubishi PLC

- Honeywell PLC

- Omron PLC

- Schneider PLC

- Hitachi PLC

- Fatek PLC

- Bosch PLC

- GE (General Electric) PLC

Q16. What are the advantages of the PLC over the Hardware Relay?

- The following are the advantages of PLC over the hardware relay. PLC occurs in both software and hardware base. But relay occurs in only hardware base.

- PLC can easily monitor and control the device than the relay.

- It is easy to find out the fault in PLC software.

- PLC provides more working functions and features than the relay.

- PLC provides more flexibility and reliability than the relay.

- It is easy to modify and implement PLC programming logic than the relay.

Q17. Explain the functions of PLC.

- The functions of the PLC are, Sequential computerized controlling

- Monitoring the system and plant

- Operating the position or motion of the system

- Detecting the fault condition in the system

Q18. What is the major area of applications of PLC?

- PLC has multiple applications in various sectors. PLC is needful in the industrial sector like the steel industry, glass industry, cement industry, paper mill, coal mine, automobile industry, chemical industry, textile industry, robotic system, and food processing system.

- It is used in the electrical transmission and distribution power station.

- It is used for domestic purposes in remote sensing devices.

- PLC is also useful for educational purposes such as academic and research projects.

- PLC is mostly used for commercial and educational purposes.

Q19. What are the main advantages of PLC?

- There are various advantages of PLC.PLC (especially Compact PLC) has a lower cost associated with it as compared to the other automation technology.

- It provides a more reliable solution.

- Even for beginners, programming used for PLC is easy to write and to understand, and to implement the logic. Among all PLC programming, LD language is the easiest one.

- One of the major advantages is, PLC is easy to communicate and connect with the computer. There are various standard communication protocols available in PLC.

- PLC (especially Compact PLC) does not take much space. They are smaller in size.

- PLC operates very fast (almost no booting time).

- Performing modification is possible and very much easy. You can easily make the changes in an already implemented design logic.

- PLC has low maintenance associated with it.

- PLC programming provides modularity. Modular design makes development easy.

- As we have seen earlier, PLC has a fast scan time (near about 10-15 milliseconds). It requires very less operation time to perform any task.

Q20. What are the disadvantages of PLC?

- With PLC, you can operate only one program at a time.

- You cannot run multiple PLC programs simultaneously.

- There are some working environment limitations associated with PLC. The performance decreases in certain cases like high temperature, and vibration conditions.

Conclusion

These are the PLC interview questions and answers asked in many company interview rounds.